How the forest industry structure is changing

New and emerging markets

The globalization of forest markets continues to drive the transformation of the Canadian forest sector. Consequently, competition in export markets is intensifying. For instance, new entrants from Europe, South America and Russia now offer significant competition to Canadian exporters in markets where they had previously dominated. Globalization also means that international firms are interested in investing in Canada, particularly in the pulp and paper segments. Similarly, Canadian firms are investing abroad with significant investments in the United States and in Europe over the past few years.

Multiple factors provide an impetus for the forest sector to seize opportunities that will transform it into a world leader of innovative, sustainable forest products. Globalization, the declining demand for some traditional products such as newsprint, growing protectionism, the cumulative effects of forest disturbances from climate change, and an increasing global commitment to clean growth all play key roles.

Low-carbon projects (and products) that meet future market demand and consumer preferences are key to supporting a forest sector transition towards the bioeconomy. Such projects include bioplastics, bio-refineries, nano-cellulose crystals, sugars used in chemicals, and artificial intelligence for real time operations. This transition towards the bioeconomy will help the sector be more resilient to fibre supply challenges and changing markets.

Low-carbon projects (and products) that meet future market demand and consumer preferences are key to supporting a forest sector transition towards the bioeconomy. Such projects include bioplastics, bio-refineries, nano-cellulose crystals, sugars used in chemicals, and artificial intelligence for real time operations. This transition towards the bioeconomy will help the sector be more resilient to fibre supply challenges and changing markets.

Today, you may be wearing clothes made from rayon that started out as pulp from Canadian trees. Wood fibre is strengthening composite car parts, making vehicles lighter, reducing emissions, and replacing plastics made from non-renewable fossil resources. Also, cellulose from trees is found in the screens of your smart phones and the paint on your walls.

Leveraging local resources

Leveraging local resources to mitigate or adapt to climate change has become a priority. Nature-based solutions that are focused on forest carbon sequestration or decreasing the risk of wildfire, are attracting interest from large non-forest sector multinationals and small Canadian communities alike.

Leveraging local forest resources also offers increasing opportunities for rural and Indigenous communities to develop new economic activities. For instance, with increasing Indigenous-held tenure agreements, Indigenous communities are building forest management expertise and turning to bioenergy to lessen their dependency on trucked-in diesel.

Next-gen products

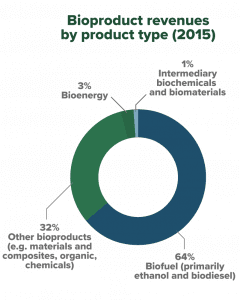

The forest industry is a leader in finding new ways to use forest biomass to offset GHG emissions while adding value to our emerging bioeconomy. In the bioeconomy, renewable and sustainably sourced biomass resources are used to provide a greater range of consumer and industrial products to society.

These biomass resources come from trees, agricultural crops and organic residuals from harvesting and timber processing with potential products ranging from food additives and textiles to construction materials, auto parts, bioplastics, biochemicals, and biofuel for vehicles and planes. Biofuels are also being used to generate heat and power, including in remote communities, thereby displacing higher-emitting fuels such as diesel.

Finding a use for every part of the tree

Canadian forest sector companies strive to find a use for every part of the tree and in doing so help to grow Canada’s bioeconomy. For example, sawmills generate residues in the form of wood chips or sawdust. These residues are valuable and can be processed into panels, paper products, or wood pellets, for both domestic use and international export. In fact, these efforts have contributed to a 53 per cent reduction in total fossil GHG emissions (direct and indirect emissions) from the forest industry between 2005 and 2020.

Transparent wood, 3D printing, and stealth technology

Canadians live surrounded by traditional forest products, whether it is construction lumber, mulch in the garden or paper coffee cups. However, Canadians might be surprised to learn that scientists and entrepreneurs are increasingly using forest biomass in items such as cellphone screens, concrete blocks, and batteries. These non-traditional uses are growing and strengthening Canada’s bioeconomy.

Transforming waste into high-value materials

Innovative forest-based materials, created by using cutting-edge science and creative thinking, are increasingly available commercially as alternatives to traditional, non-renewable materials. Looking for ways to grow the added value of their supply chain, the pulp and paper industry is keenly interested in the conversion of their waste products into specialty products.

For example, lignin is a component of wood fibre that is separated out during the pulping process. It can be used to create densified wood that is as strong as steel or transparent wood that is stronger and more insulating than glass. Of significant note, lignin, after cellulose, is the most abundant renewable carbon source on Earth. Lignin can also be used to make new products such as carbon foam — a strong, lightweight material capable of absorbing sound and radiation, which can be used for aircraft and ship insulation, wall panels and stealth technology.

Continuing innovation

The forest sector is evolving, providing new ways for forests to benefit all Canadians. Increasing innovation in the sector is producing a variety of new renewable and sustainable bioproducts which are all part of diversifying the forest sector and expanding the bioeconomy.

The opportunities for innovation include increasing the utilization of biomass from harvested sites. Biomass is not considered traditionally to be of commercial value and is usually left in the forest. This biomass, including branches and small hardwood trees, can be processed into wood chips, at which point resin is extracted from the wood. The biomass remaining after the resin extraction is processed into a bioplastic polymer, and the resin and polymer are then recombined using proprietary technology to create a strong, lightweight bioplastic that can then be used in 3D printers. In a 3D printer, the bioplastic is heated and extruded through a nozzle, depositing layer after layer of bioplastic until it forms a complete three-dimensional object.

Other examples of innovation include the production of engineered wood fibre mats to replace fibreglass components in cars, the repurposing of rubber plants to produce a component of traditional plastic soda bottles from biomaterials such as cardboard and sawdust, and the conversion of sawmill residue into 40 million litres of renewably sourced heating oil per year.

As global forest product markets evolve, innovation is essential for the competitiveness of the Canadian forest sector and the communities it sustains. It is also a critical component of the sector’s continued environmental excellence.

CCFM Innovation Committee

In 2013, the CCFM Innovation Committee was created to advance innovation-related topics relevant across jurisdictions in support of the ongoing competitiveness of the Canadian forest sector. This includes information sharing and priority setting, with recommendations on areas for action being presented to CCFM Deputy Ministers. The CCFM Innovation Committee is co-chaired by British Columbia and Natural Resources Canada.